Basic introduction:

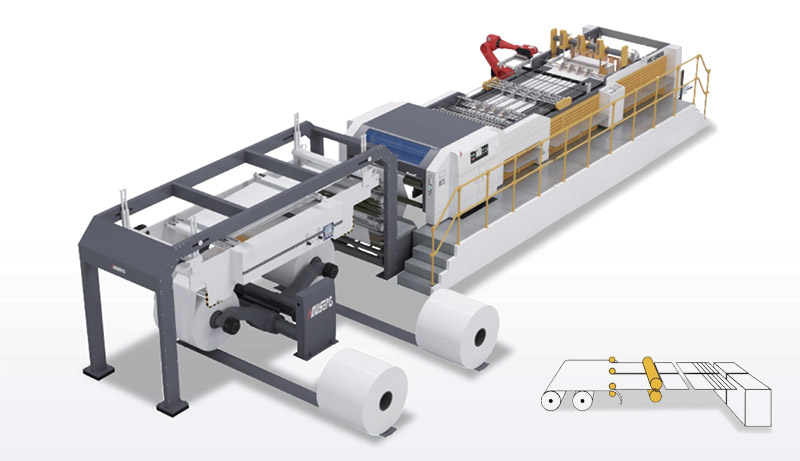

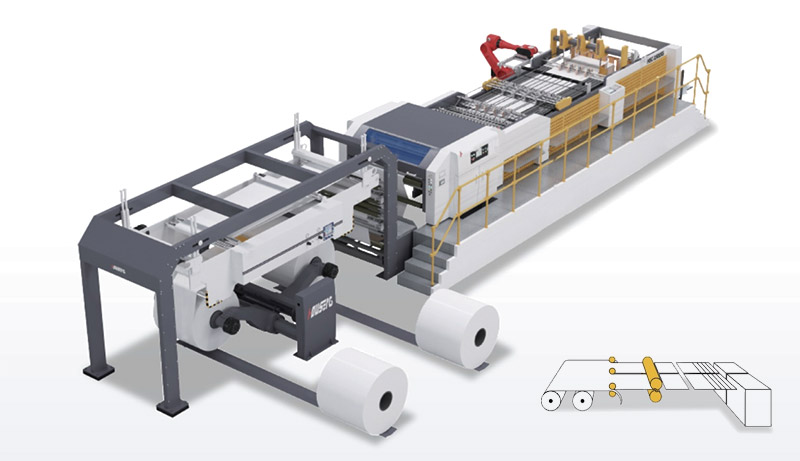

Houseng's highest-end products, realizing non-stop paper collection, can quickly adjust the production plan, shorten the production cycle, and greatly save time and labor costs.

Basic introduction:

Houseng's highest-end products, realizing non-stop paper collection, can quickly adjust the production plan, shorten the production cycle, and greatly save time and labor costs.

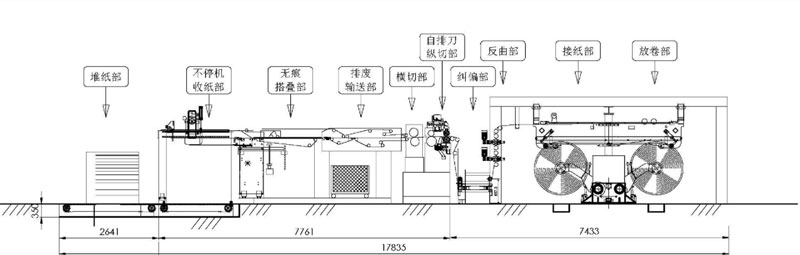

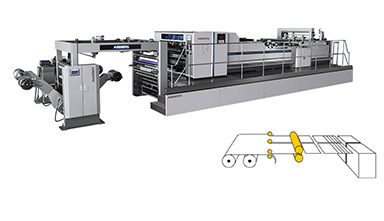

Automatic paper roll-to-sheet cutter machine is a machine that can automatically turn large paper rolls into single sheets of paper. It is manufactured by the Chinese Houseng brand cardboard manufacturer. It is characterized by double helix rotary knife cutting, high precision, high-speed rotation, cost-effective, improves efficiency, and reduces paper loss.

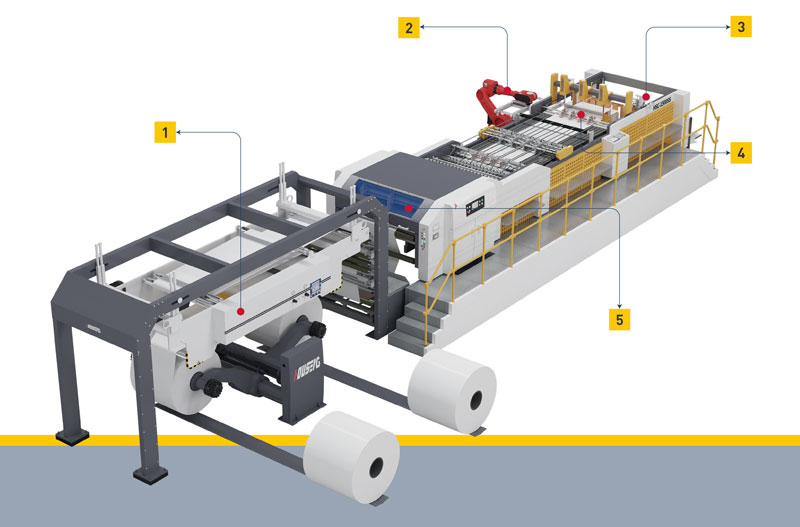

1. Automatic Splicer

High performance automatic twin-head paper splicer with Taiwan control system, can splice paper automatically, perform out by high flexibility and long service life, suitable for base paper which grams of 80g/m²-400g/m².

2. Intelligent Pallet Placement

6 degrees of freedom industrial robot is an universal type easy to maintain. Equipped with an high-precision reducer on each joint, it can flexibly complete works like handling, stacking, assembly and injection molding.

3. Auto-Material Flow

The tray chain conveyor mainly adopts 5 rows of straight chain conveyor, and uses the motor drive the material transport in ultra-low position straightly, which is a modular design and reach high degree of standardization. Hidden photoelectric switch can prevent photoelectric sensor or cardboard damage, servo motor built-in to save space, reversible operation, fexible adjustment, basically mainte-nance-free.

4. Non-Stop Paper Collection

Combined the international advanced concept, we designed non-stop paper collection system, is the latest product with independent intellectual property rights we won. lt is composed of short insert plate, long insert plate, friction belt and various auxiliary accessories. When the paper on the lifting platform reaches the rated amount, the short insert board lifts the end of the subsequent paper, and the long one hold the stack to act as collecting platform, so that workers or other automatic equipment can carry the stack. So as to achieve non-stop and continuous paper collecting, effectivelyimprove effciency and reduce costs.

5. Slitting & Trimming Knives Automatic Change System

APS-L series high-precision automatic positioning and slitting system matches high-precision sliting requirements. inteligently, accurately and rapidly, the sliting and trimming knives is auto-changing by manipulator,thus greatly improving the ability and effciency when product variety changing.According to different cutting requirements, it can work out diferent cutting solutions by coordinating with different knife, such as automatic type, manual type, connected type and pressure cutting type sliting knife, and electronic knife, etc.

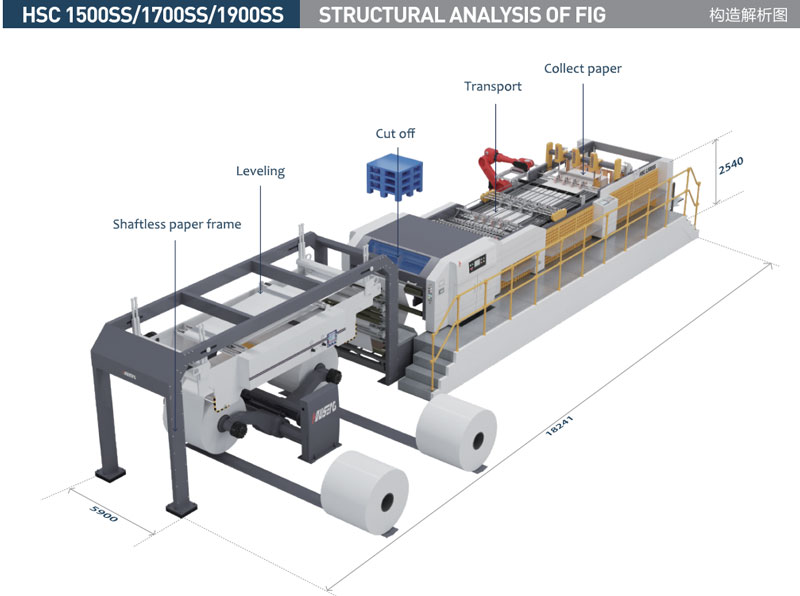

| ITEM | PARAMETERS | Cutting Length | Speed(m/min) | Speed lcuts/min) |

| Model | HSC 1500SS/1700SS/1900SS | 1600≤X | 210 | <131 |

| Cutting Pattern | Double rotary sheeter | 1400≤X<1600 | 260 | ≥162<185 |

| Range ofGram Weight | 80-1000gsm | 1200≤X<1400 | 280 | ≥200<233 |

| Max.Roll Diameter | 1800mm(71”)Max | 1000≤X<1200 | 300 | ≥250<300 |

| Max.Paper Cutting Width | 1500mm/1700mm/1900mm | 800≤X<1000 | 300 | ≥300<375 |

| Total Power | 108kW | 700≤X<800 | 300 | ≥375<400 |

| Cutting Length | 400-1650mm | 650≤X<700 | 230 | ≥328<353 |

| Cutting Accuracy | +/-0.15mm | 600≤X<650 | 180 | ≥246<300 |

| Air Compressor Requirement | 0.8MPa | 550≤X<600 | 160 | ≥266<290 |

| Weight | 26000kgs/28000kgs | 500≤X<550 | 120 | ≥218<240 |

| Overall Dimension | L18241×W5900×H2533mm | 450≤X<500 | 90 | ≥180<200 |

| 400≤X<450 | 70 | ≥155<175 |

cardboard paper, coated paper, kraft paper, cultural paper, writing paper, double qummed paper, glos photo paper, gold and siliver cardboard, aluminum paper, laser paper, packaging paper etc.

HSC-SS series run with high precision, stable operation, low energy consumption and high effciency, are developed by technology from German and decades years of experience we have. lt's widely used in the paper industry and printing industry. Perform well in cardboard paper, coated paper, kraft paper, culture paper, double gummed paper, gloss photo paper, gold and silver cardboard, aluminum paper, laser paper, packaging paper etc.

Double rotary spiral cutter rollers can cut paper clearly in less force; German precision bearing and cutting knife achieve high cutting precision; Touch interface control is easy to operate; The reasonable infection device can remove the curled paler effectively, thus strength tension of the paper roll. Sheets can directly into printing without trimming after cutting, which do improve economic effciency, reduce production costs.

1.Automatic paper roll to sheet cutter machine adopts advanced design of synchronic rotary which are driven directly by high power AC servo motor with high accuracy and clean cut.

2.And using our patent with embedded cutting head design, that its cutting cross profile is straight and not pulling out fibers, this is key point to eliminate hairs of paper. Widely used for cutting cardboard, coated paper, Kraft paper, culture paper, art paper, duplex, packaging paper etc up to 1000gsm.

3.HOUSENG machine is dedicated to produce sheet cutter, Products are well used and verified by almost all top cosmetics and pharmaceutical packaging customers, and promise their is no risk for long term running of your products in future. Consider this kind of machine to improve quality and save cost, To improve efficiency.

According to HOUSENG MACHINE, are mainly used for paper cutting in Paper Mill, Printing House and etc.

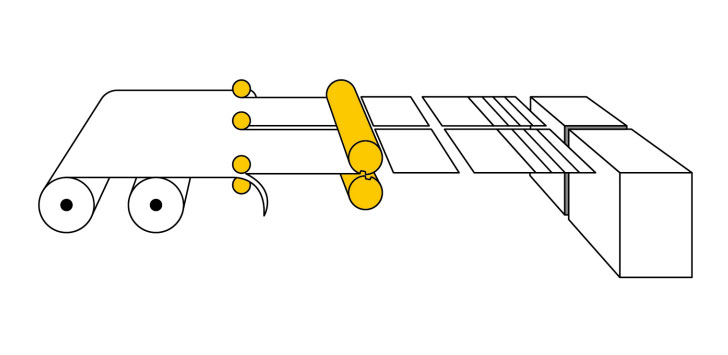

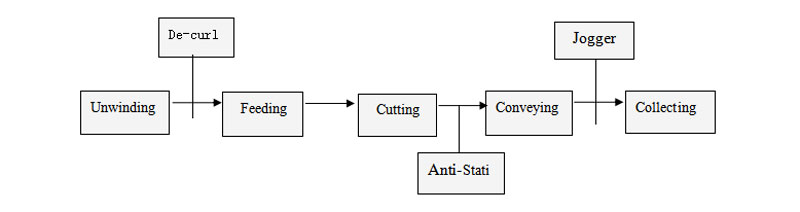

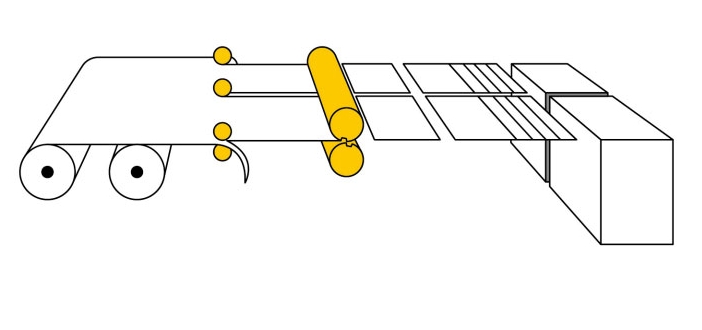

Mainly process, including: Unwinding—Feeding—Cutting—Conveying—Collecting .

HSC1500S/1700S/1900S high-precision double-spiral slitting machine is a new product developed by our company using German technology and combined with many years of experience in producing paper cutters, which is high-precision, stable in operation, energy-saving and efficient. Widely used in cardboard, coated paper, kraft paper, cultural paper, offset paper, high-gloss photo paper, gold and silver cardboard, aluminum foil paper, laser paper, tobacco and wine packaging paper, etc.

The cutter roller adopts a double-rotating spiral cutter roller design, which has small cutting force, clean paper cross-section, high efficiency, and stable rotation; German precision bearings and cutting knives provide high cutting accuracy; light-touch computer interface control, easy to operate; well-designed feedback The curling device can effectively remove the curl of the paper roll, making the paper flatter, which is more conducive to the stability of the paper roll tension.

|

|

|

|

|

|

|

| Auto-Splicer | Motorized Double Decurler | Slitting & Trimming Knives Automatic Change System |

|

|

|

| Double Rotary Sheeter Group | Conveying Overlap Part | Collection |

| Cutting Unit The double KNIFE cutting unit has a synchronic rotary cutting knife like scissors on the material to make a smooth and accurate cutting for paper from 150gsm and up to 1000gsm. The knife roller is using the most powerful driver from UK CT. Precision rotary sheeter groove is processed by imported advance processing center with high accuracy and stability, High quality gear box, using no clearance design gear. which guarantees the stability of the tool body during high-speed operation, completely solve the problem of scratches and light spots, after cutting the edge is neat and smooth, clean cut. |

|

|

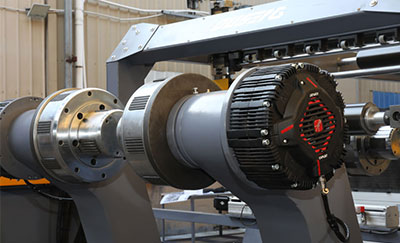

Double Arm Unwind stand with web tension controls and pneumatic brake units. Adopt Italian RE control system and pneumatic components are adopted to guarantee the stable operation of the brake control system and the accuracy of every aerodynamic action. |

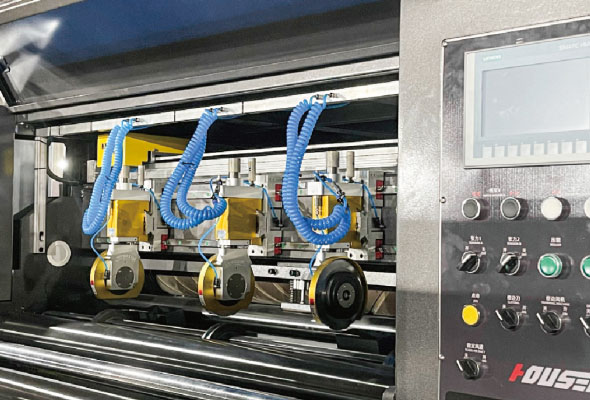

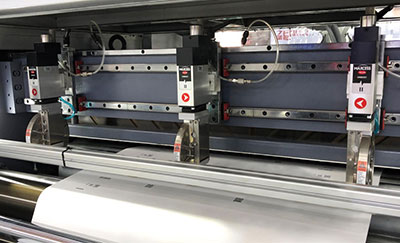

| Three sets of MAXCESS pneumatic slitting knife ensure stable and clean slitting, High rigid tool post article can be applied to 400cut/min speed environment, improve the production efficiency and ensure the material quality stability. |

|

|

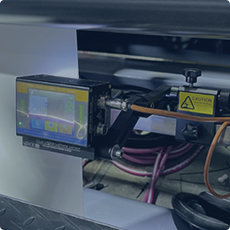

Electric control part Adopt German imports of Siemens PLC and UK OF CT servo drive control system, make the operation more convenient, automation, cutting length, number and the total number of finished products, etc., can be directly in touch screen input. High efficiency and energy saving of high power CT servo drive rotary knife shaft, and cooperate with the energy storage tank, effectively reduce electricity consumption, improve the efficiency, reduce the production cost. |

| Transportation parts Patent device-A precision structure can adjust the synchronous deceleration wheel, easy to operate, it is effective to protect surface of paper, so there will be no scratching on surface, and also will not have the facula whenever speed is high or low. |

|

|

Automatic splicer (optional) High performance automatic splicer is twin-head automatic paper machine. The control system is from Taiwan with the features of long service life, high flexibility, and automatic splicer as soon as the imperfect broken paper is sensed, easily for operation for 100 to 500 GSM papers. |

| Slitting & trimming knives automatic change (optional) The slitting & trimming knives are rapidly automatically changed by through a pair of smart and precision mechanical hands, which can greatly improve your production efficiency and its production performance on the frequent size changes of paper. According to different cutting requirements, It can be coordinate with different knife type to form a different cutting solutions for different cutting requirements, such as electronic knife, automatic type, manual type, Siamese type, press-cutting type, etc. |

|

|

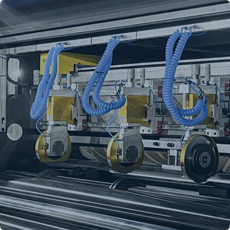

Automatic logistics system: Tray chain conveyor mainly adopts five row straight plate chain transport, motor driven design, its function is to achieve linear material transport, ultra-low transport. A series of pallet chain conveyors combined in series with each other have realized the long or short distance linear conveying of materials according to the region and process design. Modular design, high degree of standardization, flexible process arrangement and adjustment, the equipment is basically maintenance-free. |

| Intelligent tray placement Six degrees of freedom industrial robot is a general robot, the shape of the robot is tight All joints are installed with high-precision reducer, high-speed joint speed can carry out flexible operation, can carry out handling, palletizing, assembly, injection molding and other operations, with flexible installation mode. Reasonable design fixture, simple structure, convenient maintenance. |

|

AUTOMATIC SPLICER

SITTING & TRIMMING KNIVES AUTOMATIC CHANGE SYSTEM

PLATFORM WEIGHING SCALE SYSTEM

INFRARED ALIGN AUTO-ADJUSTMENT

COLOR CODESENSOR

DEDUSTING ROLLERS

PALLET PUSHER

AUTO-MATERIALFLOW

INKJET CODING SYSTEM

Optional

Functions Details

60 working days.

80-1000g.

Various optional functions have been added to achieve automatic running without stopping the machine.

2025/10/09

2025/10/09In today’s fast-paced work and creative environments, efficient paper processing is no longer a luxury—it’s a necessity. From trimming office documents to preparing materials for production, the Paper Sheet Cutter Machine stands out as a foundational tool that bridges the gap between messy paper stacks and polished, uniform results. Its versatility means it fits seamlessly into diverse industries, solving common pain points like uneven cuts, wasted materials, and time-consuming manual work. Whether you’re a small business owner, a teacher, or a production manager, understanding how this machine works can transform your daily workflows.

The printing and packaging sectors demand precision, and an industrial-grade Paper Sheet Cutter Machine is non-negotiable here. When producing bulk items like product catalogs, brochures, or packaging inserts, every sheet must be identical to ensure proper assembly and a professional finish. A high-precision Paper Sheet Cutter Machine can handle hundreds of sheets at once, maintaining accuracy even with heavy use—critical for avoiding costly reprints due to cutting errors. For packaging specifically, consistent cuts directly impact customer experience: a slightly uneven box flap or insert can ruin unboxing, so manufacturers rely on these machines to uphold quality standards. They also adapt to diverse materials, from glossy flyer paper to thick cardboard, making them versatile for mixed production runs.

Small businesses and handicraft makers often operate with limited staff, so efficiency tools like a reliable Paper Sheet Cutter Machine are game-changers. Consider a small notebook maker: every inner page and cover must align perfectly to look professional. A size-adjustable Paper Sheet Cutter Machine lets them set a fixed dimension and repeat cuts quickly, eliminating the need for extra labor. Similarly, artisans making paper decor (origami garlands, lanterns) use these machines to cut uniform shapes in bulk, speeding up production while keeping quality high. For these businesses, the machine isn’t just a cost-saver—it’s a way to scale operations, meet customer demand, and compete with larger brands through polished, consistent products.

Offices are where Paper Sheet Cutter Machines first prove their value in everyday use. Think about the tasks that pile up: preparing meeting agendas that need A3 sheets trimmed to A4, cutting promotional flyers into standard sizes, or creating uniform business cards from larger paper stock. A portable Paper Sheet Cutter Machine eliminates the frustration of manual cutting—no more lopsided edges that waste paper, or spending 20 minutes on a task that should take 2. Even small teams benefit: administrative staff can focus on client work instead of tedious trimming, and sensitive documents are handled safely (many models include safety locks to prevent accidents). For offices that prioritize efficiency, this machine isn’t just a tool—it’s a time-saver that keeps workflows on track.

Schools and creative studios rely on Paper Sheet Cutter Machines to turn ideas into tangible materials. In classrooms, teachers use small-scale models to create teaching aids—flashcards for language lessons, colorful worksheet strips, or poster pieces for displays. Manual cutting would take hours and result in inconsistent sizes that distract from learning; a Paper Sheet Cutter Machine ensures every flashcard or worksheet is uniform, letting students focus on content. For creatives—like greeting card designers, handcraft makers, or scrapbookers—a versatile Paper Sheet Cutter Machine unlocks flexibility. It trims custom sizes (square postcards, slim bookmarks) and handles delicate materials (tissue paper for flowers, watercolor paper for art prints) without tearing. This freedom lets creatives experiment without worrying about the practicality of cutting.

From offices to factories, classrooms to studios, the Paper Sheet Cutter Machine is an unsung hero that simplifies work and elevates results. Its ability to adapt to different volumes, materials, and sizes makes it indispensable—whether you’re cutting 10 sheets or 500. Investing in one means less time on tedious tasks, less material waste, and more focus on what matters: growing your business, teaching effectively, or creating.

If you’re ready to upgrade your paper processing workflow, start by exploring Paper Sheet Cutter Machine options that fit your needs—compact models for small spaces, heavy-duty ones for large runs. Every precise cut will save you time, and every uniform sheet will boost the quality of your work.

For more insights on industrial tools, practical usage tips, and industry trends, feel free to contact HAOSHENG the for content tailored to professionals like you.

This article contains approximately 30% AI-assisted content.

2025/09/18

2025/09/18For paper packaging, printing, or gift box factories, a reliable Sheet Cutter Machine is make-or-break for daily production. But we’ve heard from countless clients: uneven cuts, frequent jams, and slow after-sales help turn their Sheet Cutter Machine from a "production booster" into a "headache." We has tailored solutions for these top 3 issues—so your Sheet Cutter Machine runs smooth, consistent, and low-trouble.

Uneven edges from a Sheet Cutter Machine aren’t just unsightly—they sink your end products. For food packaging or gift boxes, rough edges mean rejected batches; for commercial printing, misaligned cuts force you to trim extra paper, wasting material. Over time, this adds up to unnecessary costs and delayed orders.

•Precision guiding system: Before paper hits the blade, built-in guides gently align it—no more "wandering" sheets that lead to lopsided cuts.

•Wear-resistant blades: Useing Wear-resistant blades that stay sharp longer (even with daily use).

•Multiple tests: Rigorous testing is of Paramount importance in ensuring high quality

Jams are the biggest time-waster for any Sheet Cutter Machine. Whether it’s thin paper curling up or short sheets getting stuck, each jam means stopping the machine, clearing paper, and restarting—losing precious minutes every time. For busy shifts, this can cut your daily output by a noticeable amount.

Solution:

•Adaptive speed control: The Sheet Cutter Machine adjusts feeding speed based on paper thickness—fast enough for efficiency, slow enough to prevent tangles.

•Anti-curl rollers: Soft, textured rollers flatten paper as it feeds, stopping thin sheets from curling and getting stuck.

When your Sheet Cutter Machine breaks down, waiting weeks for help is a disaster. Overseas clients especially struggle—spare parts take forever to arrive, and engineers are hard to schedule. Even small issues (like a finicky sensor) can shut down production for days.

•Remote diagnosis: Our team accesses your Sheet Cutter Machine’s data online to fix 80% of small issues in hours—no need to wait for an on-site visit.

•Local spare parts: We keep key parts in major regions, so replacements ship fast if you need them.

A good Sheet Cutter Machine shouldn’t just "cut paper"—it should solve your daily headaches. Haosheng’s design focuses on what you need: clean cuts, no jams, and fast help when things go wrong. Reach out today for of Haosheng , or chat with our team about a custom solution for your factory. No more uneven edges, no more jams—just smooth, reliable cutting.

2025/09/08

2025/09/08In the foreign trade export market, businesses often face the challenge of selecting cardboard cutting equipment that balances quality, efficiency, and cost. This article will break down its classifications, practical applications, and key purchasing tips to help you find the high cost-performance cardboard cutting equipment that fits your needs.

•Automatic Paper Sheet Cutting Machine: Designed for large-batch foreign trade orders. It features continuous cutting capabilities, driven by an advanced control system that minimizes manual intervention. This type significantly boosts production efficiency, making it suitable for factories handling high-volume cardboard processing for export markets like Europe and Southeast Asia.

•Semi-automatic Paper Sheet Cutting Machine: A cost-effective option for medium-scale production. It combines mechanical cutting precision with simple manual operation, reducing both investment costs and training time for workers. Small and medium-sized foreign trade enterprises (SMEs) often favor this model for its balance of performance and affordability.

•Manual Paper Sheet Cutting Machine: Ideal for small-batch or customized export tasks (e.g., cutting special-sized cardboard for handcrafted products). It is compact, easy to transport, and requires minimal installation space—perfect for buyers with limited production sites but strict cutting accuracy requirements.

HAOSHENG offers multiple types of Paper Sheet Cutting Machine to adapt to different export order scales and production demands, ensuring versatility for foreign trade clients.

The Paper Sheet Cutting Machine plays a critical role in multiple export-oriented industries, addressing diverse cardboard processing needs:

•Packaging Industry: Foreign trade orders for electronics, toys, and daily necessities rely heavily on customized packaging. HAOSHENG’s Paper Sheet Cutting Machine can cut cardboard into various sizes (e.g., small cartons for mobile phone accessories or large boxes for furniture parts), ensuring a perfect fit for exported products and reducing shipping damage risks.

•Printing Industry: After printing brochures, catalogs, or product posters for export, precise paper cutting is essential. This machine delivers clean, smooth cutting edges, enhancing the visual quality of printed materials and meeting the high standards of overseas clients.

•Stationery Manufacturing: For exporters producing notebooks, file folders, or greeting cards, the Paper Sheet Cutting Machine ensures consistent cutting accuracy. It helps maintain uniform product specifications, a key factor in winning long-term foreign trade contracts.

When selecting a Paper Sheet Cutting Machine for foreign trade, focus on these three core aspects to ensure cost-effectiveness:

•Prioritize cutting precision: Overseas clients often have strict size requirements for cardboard products.

•Evaluate durability: Equipment lifespan directly impacts long-term costs.

•Check after-sales support: For foreign trade buyers, timely after-sales service is non-negotiable.

Choosing a suitable Paper Sheet Cutting Machine, especially High cost-performance cardboard Cutting equipment, requires a comprehensive understanding of its classification, uses, and purchasing tips. By considering your own needs, key parameters, and after-sales service, you can select equipment that meets your production requirements and brings more benefits to your business.

HAOSHENG’s Paper Sheet Cutting Machine, as a product preferred for foreign trade export, stands out for its diverse classifications, wide applications, and excellent cost-performance. If you want to learn more about HAOSHENG’s Paper Sheet Cutting Machine or get a tailored quotation, don’t hesitate to contact HAOSHENG!

GET A QUOTE