In the foreign trade export market, businesses often face the challenge of selecting cardboard cutting equipment that balances quality, efficiency, and cost. This article will break down its classifications, practical applications, and key purchasing tips to help you find the high cost-performance cardboard cutting equipment that fits your needs.

1. Classifications of Paper Sheet Cutting Machine

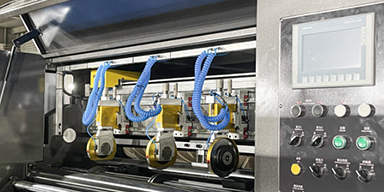

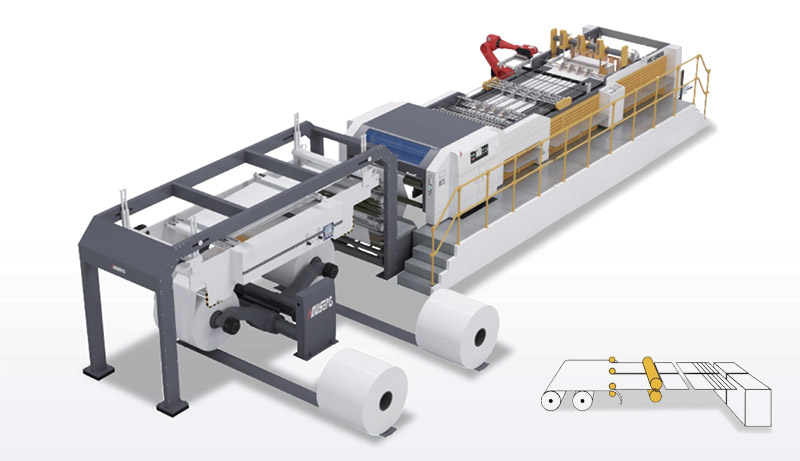

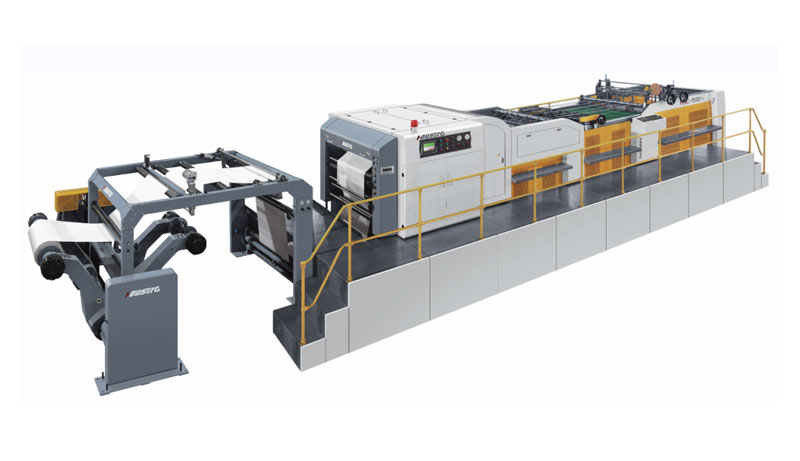

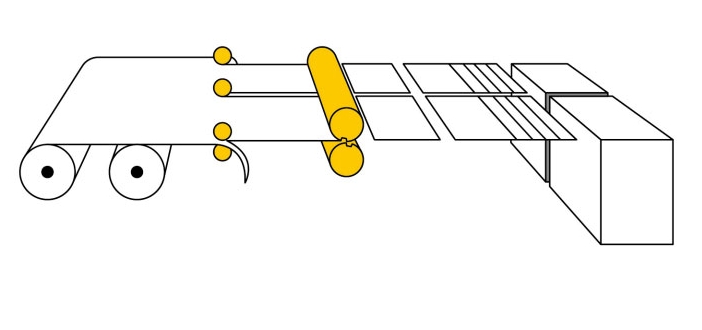

•Automatic Paper Sheet Cutting Machine: Designed for large-batch foreign trade orders. It features continuous cutting capabilities, driven by an advanced control system that minimizes manual intervention. This type significantly boosts production efficiency, making it suitable for factories handling high-volume cardboard processing for export markets like Europe and Southeast Asia.

•Semi-automatic Paper Sheet Cutting Machine: A cost-effective option for medium-scale production. It combines mechanical cutting precision with simple manual operation, reducing both investment costs and training time for workers. Small and medium-sized foreign trade enterprises (SMEs) often favor this model for its balance of performance and affordability.

•Manual Paper Sheet Cutting Machine: Ideal for small-batch or customized export tasks (e.g., cutting special-sized cardboard for handcrafted products). It is compact, easy to transport, and requires minimal installation space—perfect for buyers with limited production sites but strict cutting accuracy requirements.

HAOSHENG offers multiple types of Paper Sheet Cutting Machine to adapt to different export order scales and production demands, ensuring versatility for foreign trade clients.

2. Main Applications of Paper Sheet Cutting Machine

The Paper Sheet Cutting Machine plays a critical role in multiple export-oriented industries, addressing diverse cardboard processing needs:

•Packaging Industry: Foreign trade orders for electronics, toys, and daily necessities rely heavily on customized packaging. HAOSHENG’s Paper Sheet Cutting Machine can cut cardboard into various sizes (e.g., small cartons for mobile phone accessories or large boxes for furniture parts), ensuring a perfect fit for exported products and reducing shipping damage risks.

•Printing Industry: After printing brochures, catalogs, or product posters for export, precise paper cutting is essential. This machine delivers clean, smooth cutting edges, enhancing the visual quality of printed materials and meeting the high standards of overseas clients.

•Stationery Manufacturing: For exporters producing notebooks, file folders, or greeting cards, the Paper Sheet Cutting Machine ensures consistent cutting accuracy. It helps maintain uniform product specifications, a key factor in winning long-term foreign trade contracts.

3. Guide for Purchasing High Cost-performance Paper Sheet Cutting Machine

When selecting a Paper Sheet Cutting Machine for foreign trade, focus on these three core aspects to ensure cost-effectiveness:

•Prioritize cutting precision: Overseas clients often have strict size requirements for cardboard products.

•Evaluate durability: Equipment lifespan directly impacts long-term costs.

•Check after-sales support: For foreign trade buyers, timely after-sales service is non-negotiable.

Conclusion

Choosing a suitable Paper Sheet Cutting Machine, especially High cost-performance cardboard Cutting equipment, requires a comprehensive understanding of its classification, uses, and purchasing tips. By considering your own needs, key parameters, and after-sales service, you can select equipment that meets your production requirements and brings more benefits to your business.

HAOSHENG’s Paper Sheet Cutting Machine, as a product preferred for foreign trade export, stands out for its diverse classifications, wide applications, and excellent cost-performance. If you want to learn more about HAOSHENG’s Paper Sheet Cutting Machine or get a tailored quotation, don’t hesitate to contact HAOSHENG!

2025/09/08

2025/09/08