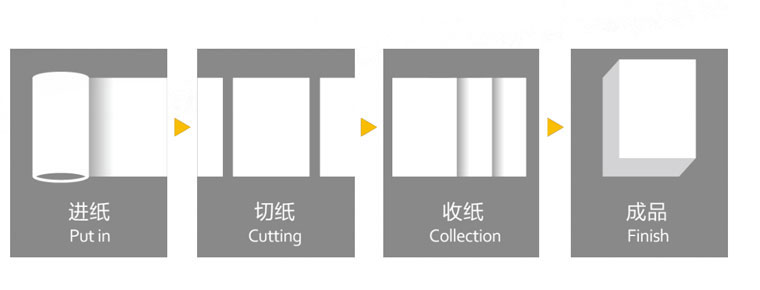

Basic introduction:

The single roll model has a small footprint and is suitable for small space operations. While retaining the advantages of the HSC-D type machine, it solves your pain point of tight production space economically.

Basic introduction:

The single roll model has a small footprint and is suitable for small space operations. While retaining the advantages of the HSC-D type machine, it solves your pain point of tight production space economically.

HSC-D is a simple but highly effective model which can reduce cost and increase benefit for your company.

• HSC-D cutter uses the advanced technology of Taiwan and Britain.

• Driven by AC servo motor.

• Cutting paper stably in high speed.

• Germany precise bearing and cutting knife assure the high precision.

• Touch interface is simple to operation.

• Reasonable inflection device ensures smooth of paper.

• This machine is widely used in paper making, paper products processing and printing industry, and will improve efficiency and increase benefit for your company.

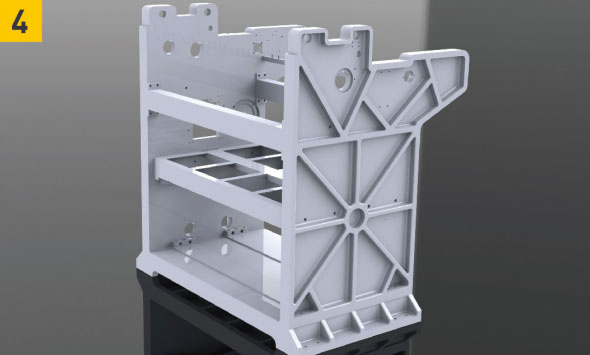

• It's achievable for casting body to realize higher speed and more stability, thus significantly improve the service life of parts.

| ITEM | PARAMETERS |

| Model | HSCJ 1100D/1400D/1700D/1900D |

| Reference weight of cutting-paper | 50-550g |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Cutting accuracy | +/-0.3mm |

| Gross weight | 14.000kgs/16.000kgs |

| Total power | 28kW |

| Power consumption | AC380V/220vx50Hz |

| Maximum cutting speed | 400cuts/min |

| Maximum cutting meter speed | 400m/min |

| Cutting length range | 400-1650mm |

| Paper-piling height | 1400mm |

| Max.roll diameter | 1800mm(71")Max |

| Maximum paper-cutting width | 1100mm/1400mm/1700mm/1900mm |

| The format of slitting | 2sheets |

| The request for air compressor | Max.5.5kg/cm2×5m3/min |

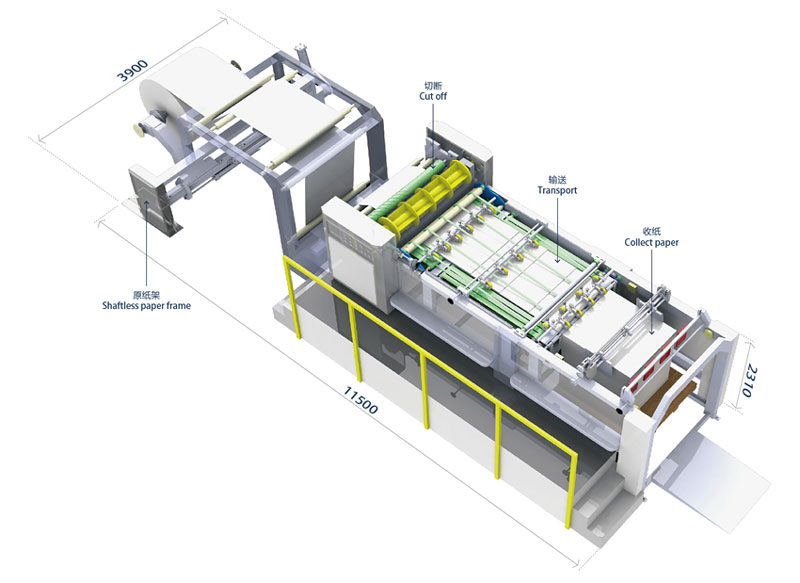

01. high-precision single knife cutting machine

02. prismatic adjustment system for paper

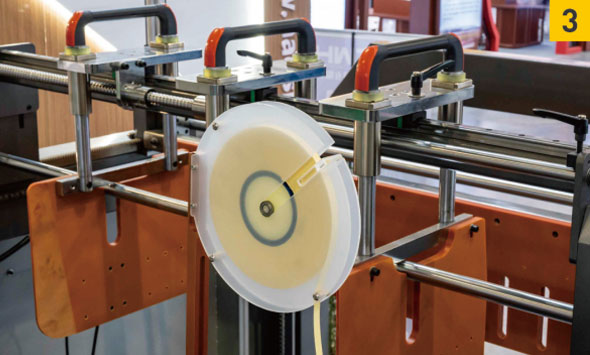

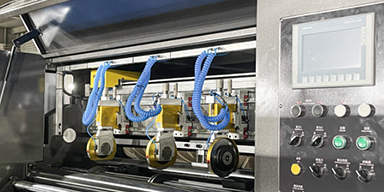

03. middle slitting and waste collection system

04. automatic counting and label inserting equipment

05. paper transporting equipment

06. automatic paper trimming and collecting machine

07. electrical controlling system

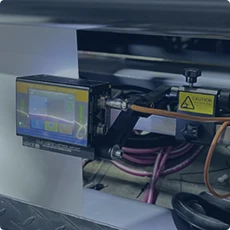

08. servo driver system

09. double lime pneumatic shaftless paper rack

|

MIDDLE SLITTING AND WASTE EDGE COLLECTING SYSTEM 1. The slitting knife at the top can be adjusted up and down, and the bottom side is fxed, 2. Use vacuum blower andY-exhaust pipe to discharge waste |

|

|

CONVEYING OVERLAP PART A precision structure can adjust the synchronous deceleration wheel easy to operate, |

|

AUTO COUNTING AND TAP INSERTER 1.Type: lnsert after counting precisely 2.Function: |

|

|

CASTING BODY The main machine wall is optimized through fnite element analysis to |

AUTOMATIC SPLICER

SITTING & TRIMMING KNIVES AUTOMATIC CHANGE SYSTEM

PLATFORM WEIGHING SCALE SYSTEM

INFRARED ALIGN AUTO-ADJUSTMENT

COLOR CODESENSOR

DEDUSTING ROLLERS

PALLET PUSHER

AUTO-MATERIALFLOW

INKJET CODING SYSTEM

Optional

Functions Details

30 working days.

50-550g.

Save production space, and easy to load paper. The cast body not only reduces mechanical vibrations to extend the service life of the machine, but also makes it more stable during high-speed operation.

2026/01/22

2026/01/22

2025/12/10

2025/12/10

2025/11/26

2025/11/26GET A QUOTE