Basic introduction:

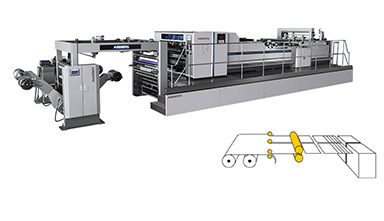

Cast body, the highest slitting knife speed can reach 400 knives / min, classic models, simple installation, convenient operation, easy to start, short training time.

Basic introduction:

Cast body, the highest slitting knife speed can reach 400 knives / min, classic models, simple installation, convenient operation, easy to start, short training time.

Automatic paper roll sheeter machine the high-quality nodular cast iron for the integration of design and through precision machining, improves the service life of the bearing parts,400 cuts/min low failure rate, and high yield efficiency.

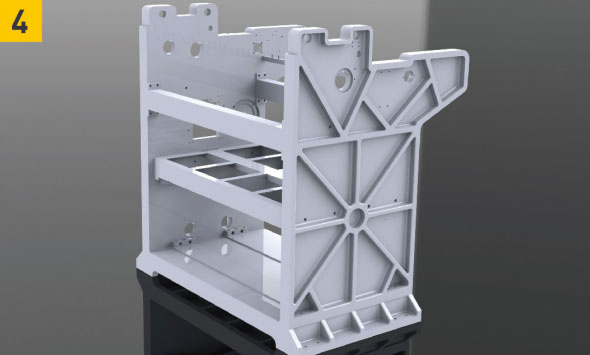

1.Paper roll sheeter machine wall through finite element analysis, mechanical vibration analysis and optimization of the frame, uses the high quality nodular cast iron for the integration of design, and through precision machining, perfect the resonance phenomenon between the transmission components, More stable in high speed operation, improve the service life of the bearing parts.

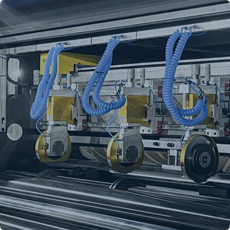

2.Upper knife roller has the British cutter method to effectively reduce the load and noise during paper cutting, and to extend the life of the cutter. The upper knife roller is welded with stainless steel for precision machining, and is dynamically balanced during high-speed operation. Lower tool seat is made of cast iron integrally formed and cast, and then precision processed, with good stability

3.Three sets of pneumatic type slitting unit to have a high speed, smooth and powerless trimming and slitting, with quick adjustment and locking. High rigidity knife holder is suitable for 300m/min high speed slitting .

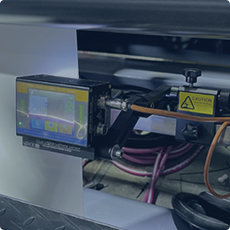

4.Touch screen controls are used to set and display sheet size, count, cut speed, delivery overlap, and more. The touch screen controls work in conjunction with a Siemens PLC.

HSC-D cutter uses the advanced technology of Taiwan and Britain.

Driven by AC servo motor.

Cutting paper stably in high speed.

Germany precise bearing and cutting knife assure the high precision.

Touch interface is simple to operation.

Reasonable inflection device ensures smooth of paper.

This machine is widely used in paper making, paper products processing and printing industry, and will improve efficiency and increase benefit for your company.

It's achievable for casting body to realize higher speed and more stability, thus significantly improve the service life of parts.

HSC-D is a simple but highly effective model which can reduce cost and increase benefit for your company.

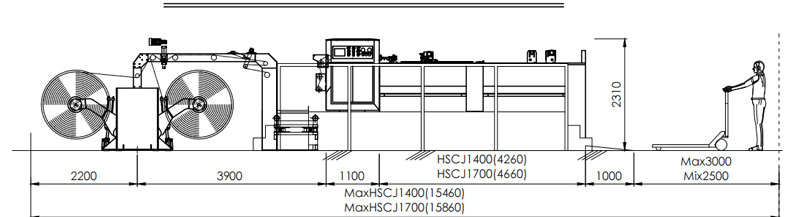

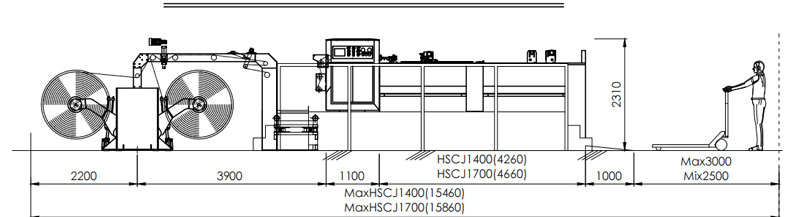

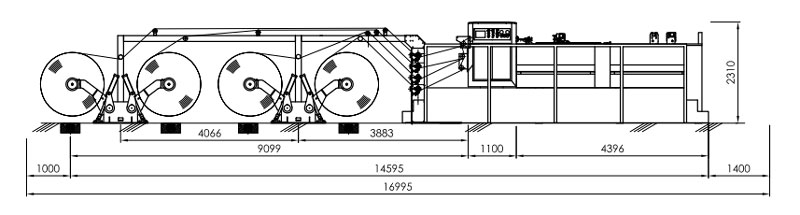

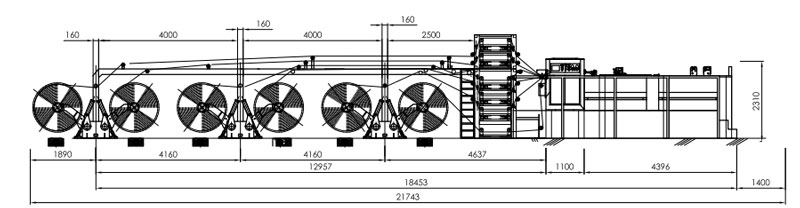

| Model | HSC-1400D/1700D |

| Reference weight of cutting-paper | 50-550g |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Cutting accuracy | +/-0.3mm |

| Gross weight | 14.000kgs/16.000kgs |

| Total power | 28kw |

| Power consumption | AC380V/220vx50HZ |

| Maximum cutting speed | 400cuts/min |

| Maximum cutting meter speed | 400m/min |

| Cutting length range | 400-1450mm/400-1650mm |

| Paper-piling height | 1400mm |

| Maximum scroll diameter | 1800mm(71"Max |

| Maximum paper-cutting width | 1400mm/1700mm |

| The format of slitting | 2sheet |

| The request for air compressor | Max.5.5kg/cm2x5m3/min |

|

1. |

Dust removal |

|

2. |

Color code tracking system |

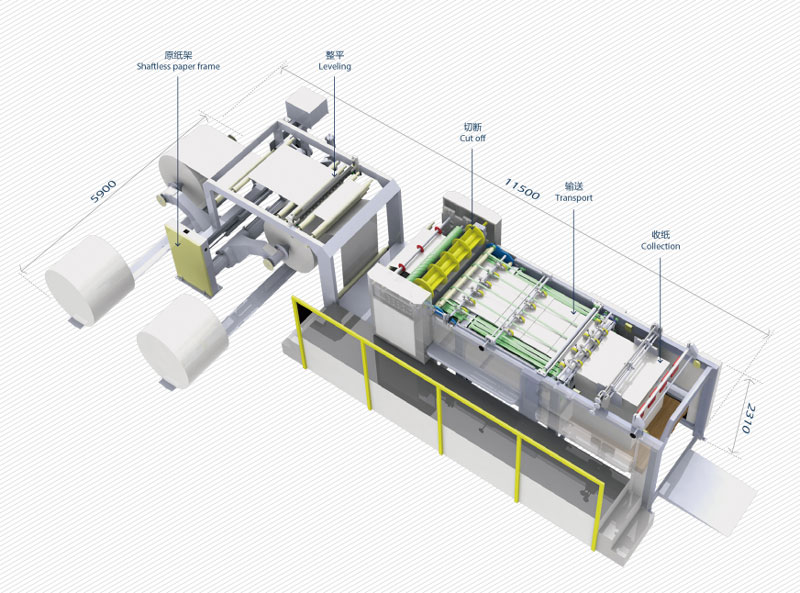

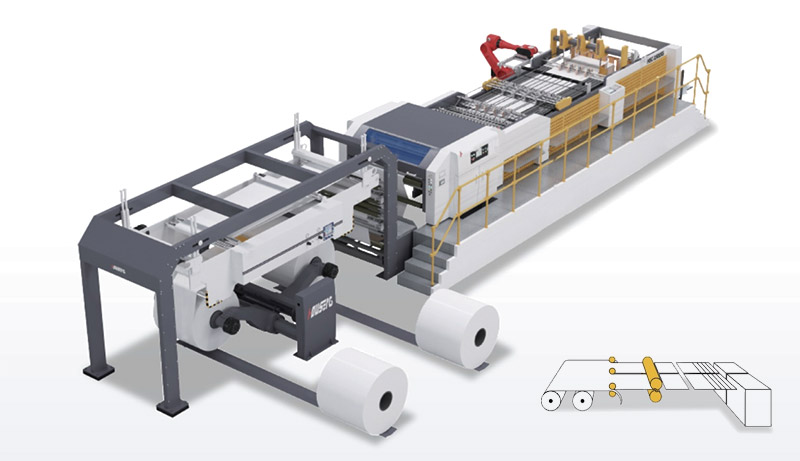

01. high-precision single knife cutting machine

02. prismatic adjustment system for paper

03. middle slitting and waste collection system

04. automatic counting and label inserting equipment

05. paper transporting equipment

06. automatic paper trimming and collecting machine

07. electrical controlling system

08. servo driver system

09. double lime pneumatic shaftless paper rack

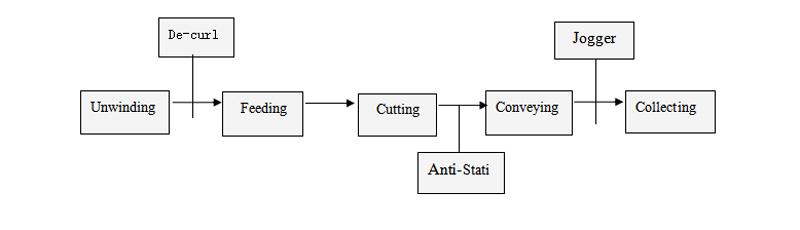

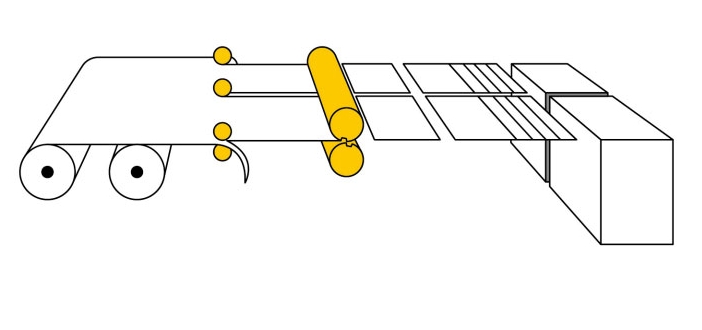

Mainly process including:Unwinding—Cutting—Conveying—Collecting.

2 reels unwinder (1 set EPC)

4 reels unwinder (3 sets EPC)

6 reels unwinder (5sets EPC)

Paper Roll Sheeter Machine is used to cut large paper rolls into individual sheets of the same size and further cut into multiple small sheets. It is widely used in printing, packaging, papermaking and other industries, and can effectively improve production efficiency and product quality.

In the printing industry, Paper Roll Sheeter Machine can accurately cut large printing paper rolls into individual sheets of required size, ensuring that the size and quality of each sheet of paper are consistent and meeting printing quality requirements. In the packaging industry, this kind of machine can cut large rolls of packaging paper into small sheets suitable for packaging boxes or bags, helping to improve the efficiency and accuracy of packaging production lines and reduce manual operations and error rates.

In addition, in the papermaking industry, Paper Roll Sheeter Machine can effectively control the size of paper, reduce waste, improve paper utilization, and also reduce energy consumption and environmental pollution during the production process.

|

|

|

|

|

CUTTING UNIT The upper knife uses British cutter method to reduce the load and |

|

|

CONVEYING OVERLAP PART A precision structure can adjust the synchronous deceleration wheel, |

|

AUTO COUNTING AND TAPINSERTER 1.Type: lnsert after counting precisely |

|

|

CASTING BODY The main machine wall is optimized through fnite element analysis, |

|

Upper knife roll has the British cutter method to reduce The knife roll block with cast iron integrally molded casting, |

|

|

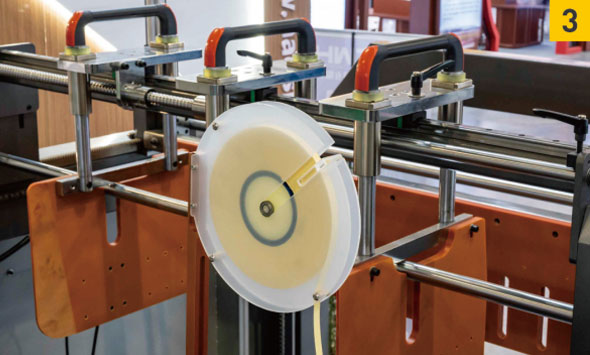

Dual position shaftless pivoting arm unwind stand 1)Max Reel Diameter: 1800mm |

|

Slitting knife Three sets of pneumatic type slitting unit to have a high speed, |

|

|

Motorized double decurler Effectively remove the curl of the roll to make the paper more flat, more conducive the paper roll tension stability, which enable this machine practically to run thick board till 200-500gsm . |

|

Delivery and Auto Jogger System Automatically goes down when paper piling up to a certain height. Conveyor system with mult-stage: from high speed to low speed. |

|

|

Electronic control YASKAWA servo,Siemens PLC,Schneider,Eaton, |

|

Delivery and Auto Jogger System The stacker table has three sides shake finishing function, |

|

|

Transport department The fast/slow speed belt is controlled by the stepless frequency converter, |

|

Auto counting and Automatic marking Type: Insert after counting precisely Auto -EPC (Edge Paper Control) Precision sensing nozzle which easily available and sensitive . Auto-tension control Put the paper roll diameter and paper weight number into touching screen, |

|

|

The main machine structure (Knife holder and holder stand) The main machine wall through finite element analysis, 1, AC Servo motor & encoder for cross knife |

AUTOMATIC SPLICER

SITTING & TRIMMING KNIVES AUTOMATIC CHANGE SYSTEM

PLATFORM WEIGHING SCALE SYSTEM

INFRARED ALIGN AUTO-ADJUSTMENT

COLOR CODESENSOR

DEDUSTING ROLLERS

PALLET PUSHER

AUTO-MATERIALFLOW

INKJET CODING SYSTEM

Optional

Functions Details

35 working days.

50-550g.

The cast body not only reduces mechanical vibrations to extend the service life of the machine, but also makes it more stable during high-speed operation. It’s an ideal single knife machine.

2025/10/09

2025/10/09In today’s fast-paced work and creative environments, efficient paper processing is no longer a luxury—it’s a necessity. From trimming office documents to preparing materials for production, the Paper Sheet Cutter Machine stands out as a foundational tool that bridges the gap between messy paper stacks and polished, uniform results. Its versatility means it fits seamlessly into diverse industries, solving common pain points like uneven cuts, wasted materials, and time-consuming manual work. Whether you’re a small business owner, a teacher, or a production manager, understanding how this machine works can transform your daily workflows.

The printing and packaging sectors demand precision, and an industrial-grade Paper Sheet Cutter Machine is non-negotiable here. When producing bulk items like product catalogs, brochures, or packaging inserts, every sheet must be identical to ensure proper assembly and a professional finish. A high-precision Paper Sheet Cutter Machine can handle hundreds of sheets at once, maintaining accuracy even with heavy use—critical for avoiding costly reprints due to cutting errors. For packaging specifically, consistent cuts directly impact customer experience: a slightly uneven box flap or insert can ruin unboxing, so manufacturers rely on these machines to uphold quality standards. They also adapt to diverse materials, from glossy flyer paper to thick cardboard, making them versatile for mixed production runs.

Small businesses and handicraft makers often operate with limited staff, so efficiency tools like a reliable Paper Sheet Cutter Machine are game-changers. Consider a small notebook maker: every inner page and cover must align perfectly to look professional. A size-adjustable Paper Sheet Cutter Machine lets them set a fixed dimension and repeat cuts quickly, eliminating the need for extra labor. Similarly, artisans making paper decor (origami garlands, lanterns) use these machines to cut uniform shapes in bulk, speeding up production while keeping quality high. For these businesses, the machine isn’t just a cost-saver—it’s a way to scale operations, meet customer demand, and compete with larger brands through polished, consistent products.

Offices are where Paper Sheet Cutter Machines first prove their value in everyday use. Think about the tasks that pile up: preparing meeting agendas that need A3 sheets trimmed to A4, cutting promotional flyers into standard sizes, or creating uniform business cards from larger paper stock. A portable Paper Sheet Cutter Machine eliminates the frustration of manual cutting—no more lopsided edges that waste paper, or spending 20 minutes on a task that should take 2. Even small teams benefit: administrative staff can focus on client work instead of tedious trimming, and sensitive documents are handled safely (many models include safety locks to prevent accidents). For offices that prioritize efficiency, this machine isn’t just a tool—it’s a time-saver that keeps workflows on track.

Schools and creative studios rely on Paper Sheet Cutter Machines to turn ideas into tangible materials. In classrooms, teachers use small-scale models to create teaching aids—flashcards for language lessons, colorful worksheet strips, or poster pieces for displays. Manual cutting would take hours and result in inconsistent sizes that distract from learning; a Paper Sheet Cutter Machine ensures every flashcard or worksheet is uniform, letting students focus on content. For creatives—like greeting card designers, handcraft makers, or scrapbookers—a versatile Paper Sheet Cutter Machine unlocks flexibility. It trims custom sizes (square postcards, slim bookmarks) and handles delicate materials (tissue paper for flowers, watercolor paper for art prints) without tearing. This freedom lets creatives experiment without worrying about the practicality of cutting.

From offices to factories, classrooms to studios, the Paper Sheet Cutter Machine is an unsung hero that simplifies work and elevates results. Its ability to adapt to different volumes, materials, and sizes makes it indispensable—whether you’re cutting 10 sheets or 500. Investing in one means less time on tedious tasks, less material waste, and more focus on what matters: growing your business, teaching effectively, or creating.

If you’re ready to upgrade your paper processing workflow, start by exploring Paper Sheet Cutter Machine options that fit your needs—compact models for small spaces, heavy-duty ones for large runs. Every precise cut will save you time, and every uniform sheet will boost the quality of your work.

For more insights on industrial tools, practical usage tips, and industry trends, feel free to contact HAOSHENG the for content tailored to professionals like you.

This article contains approximately 30% AI-assisted content.

2025/09/18

2025/09/18For paper packaging, printing, or gift box factories, a reliable Sheet Cutter Machine is make-or-break for daily production. But we’ve heard from countless clients: uneven cuts, frequent jams, and slow after-sales help turn their Sheet Cutter Machine from a "production booster" into a "headache." We has tailored solutions for these top 3 issues—so your Sheet Cutter Machine runs smooth, consistent, and low-trouble.

Uneven edges from a Sheet Cutter Machine aren’t just unsightly—they sink your end products. For food packaging or gift boxes, rough edges mean rejected batches; for commercial printing, misaligned cuts force you to trim extra paper, wasting material. Over time, this adds up to unnecessary costs and delayed orders.

•Precision guiding system: Before paper hits the blade, built-in guides gently align it—no more "wandering" sheets that lead to lopsided cuts.

•Wear-resistant blades: Useing Wear-resistant blades that stay sharp longer (even with daily use).

•Multiple tests: Rigorous testing is of Paramount importance in ensuring high quality

Jams are the biggest time-waster for any Sheet Cutter Machine. Whether it’s thin paper curling up or short sheets getting stuck, each jam means stopping the machine, clearing paper, and restarting—losing precious minutes every time. For busy shifts, this can cut your daily output by a noticeable amount.

Solution:

•Adaptive speed control: The Sheet Cutter Machine adjusts feeding speed based on paper thickness—fast enough for efficiency, slow enough to prevent tangles.

•Anti-curl rollers: Soft, textured rollers flatten paper as it feeds, stopping thin sheets from curling and getting stuck.

When your Sheet Cutter Machine breaks down, waiting weeks for help is a disaster. Overseas clients especially struggle—spare parts take forever to arrive, and engineers are hard to schedule. Even small issues (like a finicky sensor) can shut down production for days.

•Remote diagnosis: Our team accesses your Sheet Cutter Machine’s data online to fix 80% of small issues in hours—no need to wait for an on-site visit.

•Local spare parts: We keep key parts in major regions, so replacements ship fast if you need them.

A good Sheet Cutter Machine shouldn’t just "cut paper"—it should solve your daily headaches. Haosheng’s design focuses on what you need: clean cuts, no jams, and fast help when things go wrong. Reach out today for of Haosheng , or chat with our team about a custom solution for your factory. No more uneven edges, no more jams—just smooth, reliable cutting.

2025/09/08

2025/09/08In the foreign trade export market, businesses often face the challenge of selecting cardboard cutting equipment that balances quality, efficiency, and cost. This article will break down its classifications, practical applications, and key purchasing tips to help you find the high cost-performance cardboard cutting equipment that fits your needs.

•Automatic Paper Sheet Cutting Machine: Designed for large-batch foreign trade orders. It features continuous cutting capabilities, driven by an advanced control system that minimizes manual intervention. This type significantly boosts production efficiency, making it suitable for factories handling high-volume cardboard processing for export markets like Europe and Southeast Asia.

•Semi-automatic Paper Sheet Cutting Machine: A cost-effective option for medium-scale production. It combines mechanical cutting precision with simple manual operation, reducing both investment costs and training time for workers. Small and medium-sized foreign trade enterprises (SMEs) often favor this model for its balance of performance and affordability.

•Manual Paper Sheet Cutting Machine: Ideal for small-batch or customized export tasks (e.g., cutting special-sized cardboard for handcrafted products). It is compact, easy to transport, and requires minimal installation space—perfect for buyers with limited production sites but strict cutting accuracy requirements.

HAOSHENG offers multiple types of Paper Sheet Cutting Machine to adapt to different export order scales and production demands, ensuring versatility for foreign trade clients.

The Paper Sheet Cutting Machine plays a critical role in multiple export-oriented industries, addressing diverse cardboard processing needs:

•Packaging Industry: Foreign trade orders for electronics, toys, and daily necessities rely heavily on customized packaging. HAOSHENG’s Paper Sheet Cutting Machine can cut cardboard into various sizes (e.g., small cartons for mobile phone accessories or large boxes for furniture parts), ensuring a perfect fit for exported products and reducing shipping damage risks.

•Printing Industry: After printing brochures, catalogs, or product posters for export, precise paper cutting is essential. This machine delivers clean, smooth cutting edges, enhancing the visual quality of printed materials and meeting the high standards of overseas clients.

•Stationery Manufacturing: For exporters producing notebooks, file folders, or greeting cards, the Paper Sheet Cutting Machine ensures consistent cutting accuracy. It helps maintain uniform product specifications, a key factor in winning long-term foreign trade contracts.

When selecting a Paper Sheet Cutting Machine for foreign trade, focus on these three core aspects to ensure cost-effectiveness:

•Prioritize cutting precision: Overseas clients often have strict size requirements for cardboard products.

•Evaluate durability: Equipment lifespan directly impacts long-term costs.

•Check after-sales support: For foreign trade buyers, timely after-sales service is non-negotiable.

Choosing a suitable Paper Sheet Cutting Machine, especially High cost-performance cardboard Cutting equipment, requires a comprehensive understanding of its classification, uses, and purchasing tips. By considering your own needs, key parameters, and after-sales service, you can select equipment that meets your production requirements and brings more benefits to your business.

HAOSHENG’s Paper Sheet Cutting Machine, as a product preferred for foreign trade export, stands out for its diverse classifications, wide applications, and excellent cost-performance. If you want to learn more about HAOSHENG’s Paper Sheet Cutting Machine or get a tailored quotation, don’t hesitate to contact HAOSHENG!

GET A QUOTE