Basic introduction:

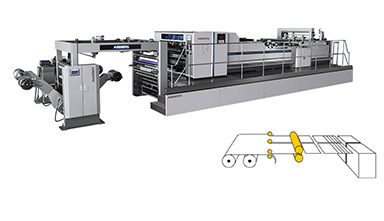

The single roll model has a small footprint and is suitable for small space operations. While retaining the advantages of the HSC-B type machine, it solves the pain point of your tight production space in an economical way.

Basic introduction:

The single roll model has a small footprint and is suitable for small space operations. While retaining the advantages of the HSC-B type machine, it solves the pain point of your tight production space in an economical way.

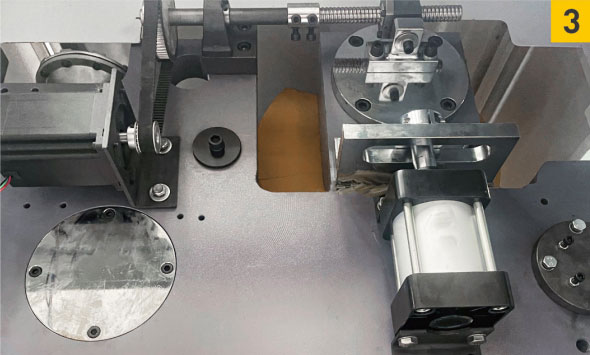

1.Upper knife roller has the British cutter method to effectively reduce the load and noise during paper cutting, and to extend the life of the cutter. The upper knife roller is welded with stainless steel for precision machining, and is dynamically balanced during high-speed operation. Lower tool seat is made of cast iron integrally formed and cast, and then precision processed, with good stability

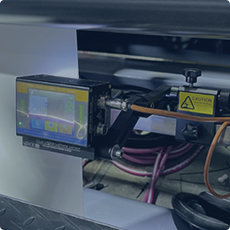

2.Touch screen controls are used to set and display sheet size, count, cut speed, delivery overlap, and more. The touch screen controls work in conjunction with a Siemens PLC.

3.Three sets of slitting knife unit to have a high speed, smooth and powerless trimming and slitting, with quick adjustment and locking. High rigidity knife holder is suitable for 300m/min high speed slitting .

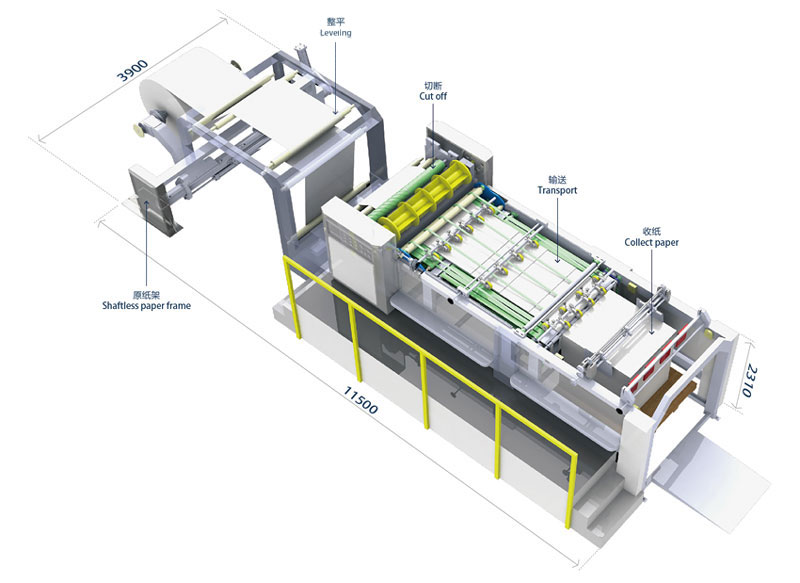

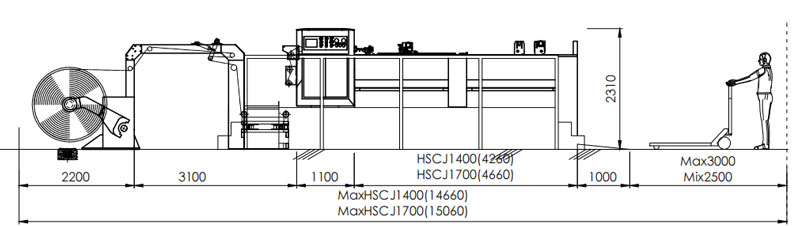

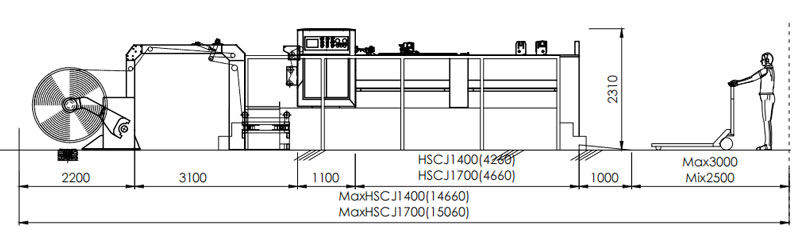

HSCJ-B series is an economical model released for customers with limited production space.

Driven by AC servo motor, controlled by UK motion, machine can cut paper stably in high speed.

Germany precise bearing and cutting knife assure the high cutting precision.

Touch interface controlis simple to operate.

Reasonable inflection device ensures smooth of paper.

The single-roll machine covers a less space, perform well in limited area and is economical.

| ITEM | PARAMETERS |

| Model | HSCJ1100B/1400B/1700B/1900B |

| Reference weight of cutting-paper | 30-550g |

| Model of cutting paper | The upper knife cut reciprocally and the down knife is fixed |

| Cutting accuracy | +/-0.3mm |

| Gross weight | 10.000kgs/13.000kgs |

| Total power | 28kW |

| Power consumption | AC380V/220vx50Hz |

| Maximum cutting speed | 300cuts/min |

| Maximum cutting meter speed | 300m/min |

| Cutting length range | 400-1650mm |

| Paper-piling height | 1400mm |

| Max.roll diameter | 1800mm(71")Max |

| Maximum paper-cutting width | 1100mm/1400mm/1700mm/1900mm |

| The format of slitting | 2sheets |

| The request for air compressor | Max.5.5kg/cm2×5m3/min |

|

1. |

Blade -Tungsten Steel |

|

2. |

Cast Iron Main |

|

3. |

Imports Of Electrical Appliances |

|

4. |

Pneumatic slitting knife |

|

5. |

Dust removal |

|

6. |

Color code tracking system |

|

7. |

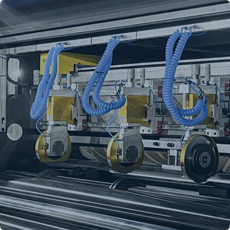

Motorized double decurler |

01.Upper knife: Use British cutting method, the upper knife roller is processed by steel welding and dynamic balance adjustment, effectively reduce vibration and noise when high-speed operation, and extend service life.

02. Lower knife: Knife holder is made by cast iron integrally molded casting and precise processing with good stability.

03.Active roller: The roller surface has a expansion pattern design and the airbag controls the roller body pressure paper.

04.Reverse knife: Made of special alloy steel, long life; The blade is easy to adjust.

05.Safety cover: Power off automatically when safety cover opened safe operation.

06.Transmission: key bearing from German FAG, other bearings from Japan NSK, assure high precision and stability.

1 reel unwinder

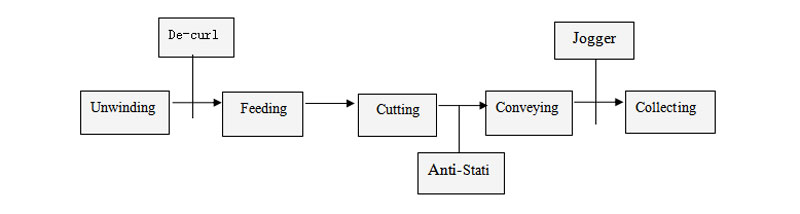

According to HOUSENG Product performance, the machine are mainly used for paper sheeting in Paper Mill, Printing House,Packaging and etc,

mainly process including: Unwinding—Cutting—Conveying—Collecting.

|

|

|

|

|

|

MOTORIZED DOUBLE DECURLER This newly designed decurler can flatten the paper with a much better |

|

|

ELECTRIC CONTROL PART The man-machine interface and HZU processor, mainly used for the |

|

AUTOMATICALLY ADJUST THE ANGLE (PAPER ALIGNING SYSTEM) The stepper motor precisely controls the precision screw and adjusts |

|

|

AUTOMATIC PILE ALLGNMENT DEVICE AT DELIVERY SECTION Lift automatically moves down when the pile is stacked to a consider- |

| Upper knife roll has the British cutter method to reduce the load and noise when the cutter extend cutter life. To steel welding gave precision machining, and dynamic balance adjustment, effectively reduce the vibration and noise of the high-speed operation. Rotary cutting knife is made of special alloy steel precision machining, with long service life and easy adjustment of the blade. Safety cover will automatically shut down when the safety cover is opened, ensuring safety. |

|

|

Dual position shaftless pivoting arm unwind stand 1)Max Reel Diameter: 1800mm |

|

Slitting knife Three sets of slitting knife unit to have a high speed, |

|

|

Delivery and Auto Jogger System Automatically goes down when paper piling up to a certain height. |

|

Electronic control INOVANCE Servo, INOVANCE PLC, Schneider, Eaton. |

|

|

Delivery and Auto Jogger System The stacker table has three sides shake finishing function, |

|

Transport department The fast/slow speed belt is controlled |

|

|

Auto counting and Automatic marking Type: Insert after counting precisely Auto-tension control Put the paper roll diameter and |

|

Driving Motor system 1, AC Servo motor & encoder for cross knife |

|

AUTOMATIC SPLICER

SITTING & TRIMMING KNIVES AUTOMATIC CHANGE SYSTEM

PLATFORM WEIGHING SCALE SYSTEM

INFRARED ALIGN AUTO-ADJUSTMENT

COLOR CODESENSOR

DEDUSTING ROLLERS

PALLET PUSHER

AUTO-MATERIALFLOW

INKJET CODING SYSTEM

Optional

Functions Details

30 working days.

50-550g.

Save production space, and easy to load paper.

2025/11/26

2025/11/26For anyone in packaging manufacturing, the right equipment doesn’t just keep lines running—it makes or breaks your ability to keep up with orders, control costs, and keep clients happy. Whether you’re cranking out food packaging that needs to meet strict hygiene standards or crafting gift boxes where every edge counts, paper sheet cutting machines tailored to packaging work aren’t just tools—they’re the backbone of your daily operations. Let’s be honest: packaging businesses face unique headaches. You’re juggling tight delivery windows, watching raw material costs climb, and adapting to endless product size changes. For food and gift packaging specifically, two needs stand out: keeping production moving without stops and nailing fast, precise cuts for short formats . So what really sets the best packaging-focused cutters apart, and how do those features translate to real, bottom-line value for your business?

Packaging isn’t a one-size-fits-all game, and the best paper sheet cutting machines get that—they’re engineered to tackle the specific demands of food and gift sectors, two of the busiest and most detail-driven corners of the industry.

Take food packaging first: non-stop production isn’t a luxury—it’s a necessity. Food manufacturers and packagers often run 24/7, especially during peak seasons like holidays or back-to-school rushes. A single halt for roll changes, adjustments, or maintenance can throw off schedules, delay shipments, and even lead to lost orders. Today’s packaging-focused cutters solve this with built-in features that keep production rolling: easy roll-to-sheet handoffs, automated alignment that cuts down on manual tweaks, and tough, long-lasting parts that hold up to round-the-clock use. And let’s not forget food safety—these machines are designed to protect the surface of food-grade paper, so there’s no contamination risk, and any coatings or laminations that meet safety standards stay intact. No more scrapping batches because the cutter damaged the paper.

Then there’s gift packaging, where short-format cutting speed and versatility are make-or-break. Think small gift tags, mini boxes, or custom-shaped wrappers—most of these fall in the 400–650mm range. Standard cutters struggle here: they jam, produce inconsistent sizes, or slow to a crawl when dealing with short lengths. But cutters made for packaging? They’re optimized for these smaller jobs, cranking out precise cuts faster than generic models. That’s a game-changer for gift packaging, where you’re often handling small-batch, custom orders that need quick turnarounds. Plus, they can handle all the decorative materials you throw at them—glossy cardstock, textured wrapping paper, lightweight craft paper—without tearing, creasing, or leaving ragged edges. For gift packaging, aesthetics matter as much as function, and these machines deliver on both.

The best part? These aren’t one-trick ponies. A good packaging cutter adapts to whichever sector you’re serving, so you don’t have to invest in separate machines for food and gift work. It aligns with your workflow, not the other way around.

Beyond fitting your industry’s needs, the top features of paper sheet cutting machines for packaging all boil down to one thing: making your business more efficient and profitable. Let’s break down the three biggest wins:

Downtime is every packager’s worst nightmare—and it’s more costly than you might think. Every minute a machine sits idle is lost production, wasted labor, and missed opportunities. The best packaging cutters are built to minimize these stops. They use durable components that don’t need constant repairs, and smart diagnostic tools that flag potential issues (like a dull blade or misalignment) before they shut down the line. For continuous production setups, features like automatic roll splicing (so you can change rolls without stopping) and quick-change blade systems cut down on interruptions even more. The result? A workflow that’s reliable, consistent, and able to meet those tight delivery deadlines without scrambling.

Raw material costs are one of the biggest expenses for packaging businesses—and waste is like throwing money away. Think about all the half-used rolls that end up in storage because standard machines can’t optimize cuts for short lengths, or the sheets that get scrapped because they’re the wrong size. Packaging-focused cutters fix this with smart cutting algorithms that map out the most efficient way to use each roll, minimizing scrap and maximizing the number of usable sheets. Their precision also means fewer mistakes—no more discarding stacks of paper because the cuts are off by a millimeter. For short-format jobs, this optimization is even more critical: generic machines leave huge amounts of waste when cutting 400–650mm sheets, but packaging cutters squeeze out every possible usable piece. Over time, this adds up to serious savings—often double-digit percentages on material costs.

When you combine less downtime and less waste, lower unit production costs follow naturally. A good packaging cutter lets you produce more sheets per hour with fewer resources: less paper wasted, less labor spent on fixing mistakes or maintaining the machine, and less energy used per unit. For high-volume operations, this scales quickly—you can crank out thousands more sheets a day without increasing your input costs, which boosts your profit margins. Even for smaller businesses, lower unit costs let you price your products more competitively, which helps you win more clients in a crowded market. It’s not just about cutting paper—it’s about cutting unnecessary expenses.

Picking the best paper sheet cutting machine for your packaging business isn’t about buying the most expensive model—it’s about finding one that fits how you work. Start by asking yourself: What do I produce most? If it’s food packaging, prioritize non-stop production and food-safe features. If it’s gift packaging, focus on short-format speed and material versatility. Then, think about volume: high-volume operations need faster speeds and more automation, while smaller batches might benefit from easy setup and user-friendly controls.

Don’t forget to plan for the future, too. Consumer preferences change, and packaging designs evolve—you don’t want a machine that can only handle your current products. Look for cutters with adjustable length ranges and the ability to work with different paper weights and types. That way, when you take on a new job or switch up your offerings, your cutter can keep up.

Whether you’re scaling your food packaging line, expanding your gift box offerings, or just tired of dealing with downtime and waste, our team of industry experts is here to help. Tell HAOSHENG about your production volumes, the materials you use, and the specific challenges you’re facing—we’ll point you to the perfect Paper Sheet Cutter Machine that checks all your boxes. Don’t let outdated equipment hold your business back. Take the first step toward smoother, more efficient, more profitable packaging production today.

This article was assisted by AI technology, with human expertise ensuring accuracy and industry relevance.

2025/10/09

2025/10/09In today’s fast-paced work and creative environments, efficient paper processing is no longer a luxury—it’s a necessity. From trimming office documents to preparing materials for production, the Paper Sheet Cutter Machine stands out as a foundational tool that bridges the gap between messy paper stacks and polished, uniform results. Its versatility means it fits seamlessly into diverse industries, solving common pain points like uneven cuts, wasted materials, and time-consuming manual work. Whether you’re a small business owner, a teacher, or a production manager, understanding how this machine works can transform your daily workflows.

The printing and packaging sectors demand precision, and an industrial-grade Paper Sheet Cutter Machine is non-negotiable here. When producing bulk items like product catalogs, brochures, or packaging inserts, every sheet must be identical to ensure proper assembly and a professional finish. A high-precision Paper Sheet Cutter Machine can handle hundreds of sheets at once, maintaining accuracy even with heavy use—critical for avoiding costly reprints due to cutting errors. For packaging specifically, consistent cuts directly impact customer experience: a slightly uneven box flap or insert can ruin unboxing, so manufacturers rely on these machines to uphold quality standards. They also adapt to diverse materials, from glossy flyer paper to thick cardboard, making them versatile for mixed production runs.

Small businesses and handicraft makers often operate with limited staff, so efficiency tools like a reliable Paper Sheet Cutter Machine are game-changers. Consider a small notebook maker: every inner page and cover must align perfectly to look professional. A size-adjustable Paper Sheet Cutter Machine lets them set a fixed dimension and repeat cuts quickly, eliminating the need for extra labor. Similarly, artisans making paper decor (origami garlands, lanterns) use these machines to cut uniform shapes in bulk, speeding up production while keeping quality high. For these businesses, the machine isn’t just a cost-saver—it’s a way to scale operations, meet customer demand, and compete with larger brands through polished, consistent products.

Offices are where Paper Sheet Cutter Machines first prove their value in everyday use. Think about the tasks that pile up: preparing meeting agendas that need A3 sheets trimmed to A4, cutting promotional flyers into standard sizes, or creating uniform business cards from larger paper stock. A portable Paper Sheet Cutter Machine eliminates the frustration of manual cutting—no more lopsided edges that waste paper, or spending 20 minutes on a task that should take 2. Even small teams benefit: administrative staff can focus on client work instead of tedious trimming, and sensitive documents are handled safely (many models include safety locks to prevent accidents). For offices that prioritize efficiency, this machine isn’t just a tool—it’s a time-saver that keeps workflows on track.

Schools and creative studios rely on Paper Sheet Cutter Machines to turn ideas into tangible materials. In classrooms, teachers use small-scale models to create teaching aids—flashcards for language lessons, colorful worksheet strips, or poster pieces for displays. Manual cutting would take hours and result in inconsistent sizes that distract from learning; a Paper Sheet Cutter Machine ensures every flashcard or worksheet is uniform, letting students focus on content. For creatives—like greeting card designers, handcraft makers, or scrapbookers—a versatile Paper Sheet Cutter Machine unlocks flexibility. It trims custom sizes (square postcards, slim bookmarks) and handles delicate materials (tissue paper for flowers, watercolor paper for art prints) without tearing. This freedom lets creatives experiment without worrying about the practicality of cutting.

From offices to factories, classrooms to studios, the Paper Sheet Cutter Machine is an unsung hero that simplifies work and elevates results. Its ability to adapt to different volumes, materials, and sizes makes it indispensable—whether you’re cutting 10 sheets or 500. Investing in one means less time on tedious tasks, less material waste, and more focus on what matters: growing your business, teaching effectively, or creating.

If you’re ready to upgrade your paper processing workflow, start by exploring Paper Sheet Cutter Machine options that fit your needs—compact models for small spaces, heavy-duty ones for large runs. Every precise cut will save you time, and every uniform sheet will boost the quality of your work.

For more insights on industrial tools, practical usage tips, and industry trends, feel free to contact HAOSHENG the for content tailored to professionals like you.

This article contains approximately 30% AI-assisted content.

2025/09/18

2025/09/18For paper packaging, printing, or gift box factories, a reliable Sheet Cutter Machine is make-or-break for daily production. But we’ve heard from countless clients: uneven cuts, frequent jams, and slow after-sales help turn their Sheet Cutter Machine from a "production booster" into a "headache." We has tailored solutions for these top 3 issues—so your Sheet Cutter Machine runs smooth, consistent, and low-trouble.

Uneven edges from a Sheet Cutter Machine aren’t just unsightly—they sink your end products. For food packaging or gift boxes, rough edges mean rejected batches; for commercial printing, misaligned cuts force you to trim extra paper, wasting material. Over time, this adds up to unnecessary costs and delayed orders.

•Precision guiding system: Before paper hits the blade, built-in guides gently align it—no more "wandering" sheets that lead to lopsided cuts.

•Wear-resistant blades: Useing Wear-resistant blades that stay sharp longer (even with daily use).

•Multiple tests: Rigorous testing is of Paramount importance in ensuring high quality

Jams are the biggest time-waster for any Sheet Cutter Machine. Whether it’s thin paper curling up or short sheets getting stuck, each jam means stopping the machine, clearing paper, and restarting—losing precious minutes every time. For busy shifts, this can cut your daily output by a noticeable amount.

Solution:

•Adaptive speed control: The Sheet Cutter Machine adjusts feeding speed based on paper thickness—fast enough for efficiency, slow enough to prevent tangles.

•Anti-curl rollers: Soft, textured rollers flatten paper as it feeds, stopping thin sheets from curling and getting stuck.

When your Sheet Cutter Machine breaks down, waiting weeks for help is a disaster. Overseas clients especially struggle—spare parts take forever to arrive, and engineers are hard to schedule. Even small issues (like a finicky sensor) can shut down production for days.

•Remote diagnosis: Our team accesses your Sheet Cutter Machine’s data online to fix 80% of small issues in hours—no need to wait for an on-site visit.

•Local spare parts: We keep key parts in major regions, so replacements ship fast if you need them.

A good Sheet Cutter Machine shouldn’t just "cut paper"—it should solve your daily headaches. Haosheng’s design focuses on what you need: clean cuts, no jams, and fast help when things go wrong. Reach out today for of Haosheng , or chat with our team about a custom solution for your factory. No more uneven edges, no more jams—just smooth, reliable cutting.

GET A QUOTE