A Sheet Cutting Machine is a specialized equipment engineered to precisely cut different kinds of sheets, such as metal sheets, plastic sheets, and paper sheets, widely used in manufacturing, construction, and printing industries. It plays a crucial role in transforming large sheets into desired sizes and shapes to meet specific production requirements.

Types of Sheet Cutting Machine

Mechanical Shearing Machine

The mechanical shearing machine operates through the relative movement of upper and lower blades. When the machine is working, the upper blade moves downward, and the lower blade remains stationary, creating a shearing force to cut the sheet.

Advantages: It has a relatively low cost and high working efficiency, making it suitable for mass production.

Disadvantages: The cutting precision is relatively low, and it is not suitable for cutting sheets with high precision requirements.

Application scenarios: It is mainly used for cutting thick metal sheets in industries such as automobile manufacturing and shipbuilding where the precision requirements are not extremely high.

Laser Cutting Machine

The laser cutting machine uses a high - energy laser beam to irradiate the surface of the sheet. The laser beam melts, vaporizes, or burns the material at the irradiated position, and then the high - pressure gas blows away the molten material to achieve the cutting purpose.

Advantages: It has extremely high cutting precision, can cut complex shapes, and has a small heat - affected zone, which does not easily deform the sheet.

Disadvantages: The equipment cost is high, and the cutting speed is relatively slow for thick sheets.

Application scenarios: It is widely used in industries such as electronics, aerospace, and precision machinery where high precision and complex shape cutting are required.

Plasma Cutting Machine

The plasma cutting machine generates a high - temperature plasma arc through ionizing gas, which melts the metal sheet, and then uses the high - speed airflow to blow away the molten metal to complete the cutting.

Advantages: It can cut thick metal sheets quickly, and has a lower cost compared to laser cutting machines for thick sheet cutting.

Disadvantages: The cutting precision is lower than that of laser cutting machines, and the heat - affected zone is larger.

Application scenarios: It is commonly used in heavy industry, such as steel structure manufacturing and ship repair, for cutting thick metal sheets.

Working Principle of Sheet Cutting Machine

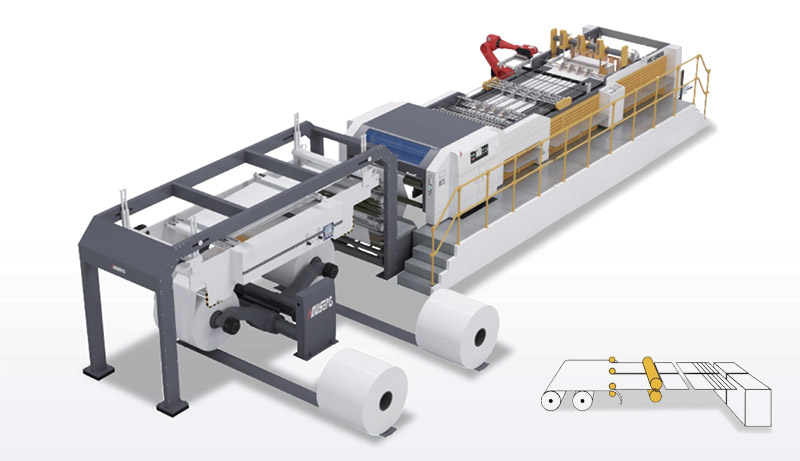

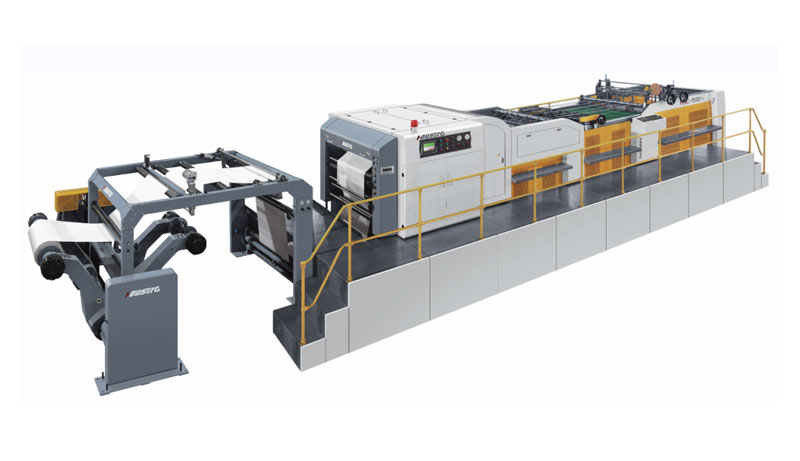

The working process of a Sheet Cutting Machine generally includes several key links: feeding, positioning, cutting, and discharging.

In the feeding stage, the sheet is transported to the working table of the machine through a feeding mechanism, which can be manual feeding or automatic feeding depending on the machine type.

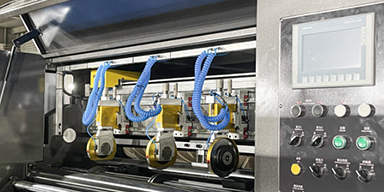

During positioning, the sheet is accurately positioned according to the preset cutting size and shape. This is usually achieved through positioning devices such as guide rails, stoppers, and sensors to ensure that the cutting position is accurate.

The cutting stage is the core part. Different types of machines use different cutting methods as mentioned earlier to cut the sheet into the desired shape and size.

Finally, in the discharging stage, the cut sheet is transported out of the working area through a discharging mechanism, which can be manual removal or automatic conveying to the next production process.

Applications of Sheet Cutting Machine

- Manufacturing industry: It is used in the production of various metal parts, plastic products, and electronic components. For example, in the automobile manufacturing industry, it cuts metal sheets into various parts of the car body; in the plastic product industry, it cuts plastic sheets into shells of various appliances.

- Construction industry: It cuts metal plates, plastic plates, and glass plates used in construction. For instance, cutting steel plates for building structures and plastic plates for decoration.

- Printing industry: It cuts paper sheets into different sizes for books, magazines, and packaging materials.

Advantages of Using Sheet Cutting Machine

- Improving production efficiency: Compared with manual cutting, Sheet Cutting Machines can complete cutting tasks quickly and continuously, greatly reducing the production time.

- Ensuring cutting quality: The machine cuts with high precision, ensuring that the size and shape of the cut sheets are consistent, reducing the rejection rate.

- Reducing labor costs: It reduces the dependence on manual labor, saving labor expenses.

- Enhancing safety: It avoids the danger of manual cutting, ensuring the safety of workers.

In conclusion, Sheet Cutting Machines are essential equipment in various industries, with different types meeting different production needs. Understanding their definitions, types, working principles, applications, and advantages is crucial for selecting the right machine for specific production tasks.

2025/07/18

2025/07/18