Introduction to Twin Knife Cutting Systems

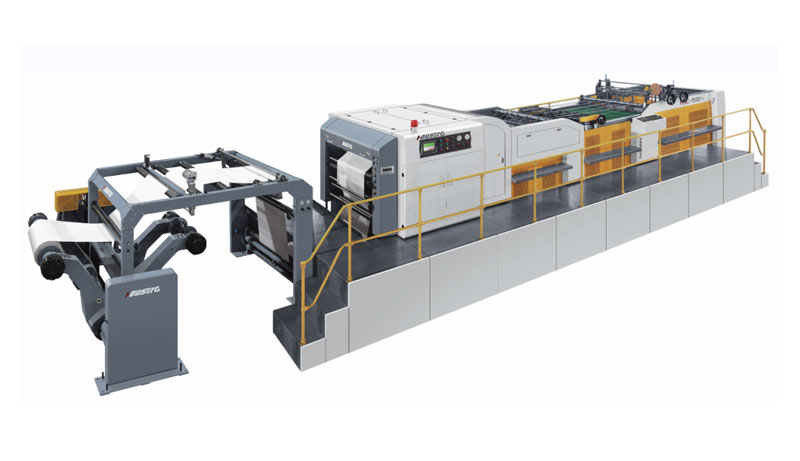

Modern industrial cutting systems rely on advanced twin knife configurations for high-speed, precision operations. The Twin Knife Sheeter and Synchro-Fly Cutter Machine represent state-of-the-art solutions for continuous production lines requiring accurate web cutting.

Core Technology Breakdown

1. Twin Knife Sheeter Mechanism

- Dual-blade configuration: Features two precisely synchronized blades for clean cuts

- Variable speed control: Adjusts to material properties and production requirements

- Continuous operation: Maintains productivity without stopping between cuts

- Material versatility: Handles paper, plastic films, textiles, and composite materials

Key specifications:

- Cutting width range: 500-3000mm

- Maximum speed: 300m/min

- Precision tolerance: ±0.2mm

2. Synchro-Fly Cutter Technology

- Rotating blade system: Maintains tangential cutting speed matching web velocity

- Electronic synchronization: Ensures perfect cut timing through encoder feedback

- Contact-free cutting: Reduces material distortion in delicate applications

- Automated blade adjustment: Compensates for wear without production stoppage

Performance metrics:

- Synchronization accuracy: 0.1mm at full speed

- Blade change time: <3 minutes

- Minimum repeat length: 150mm

Industrial Applications

Packaging Sector

Carton blank production

Flexible packaging conversion

Label sheet manufacturing

Printing & Converting

Web-fed printing operations

Laminating line integration

Roll-to-sheet processing

Composite Material Production

Fiberglass mat cutting

Non-woven fabric conversion

Carbon fiber sheet production

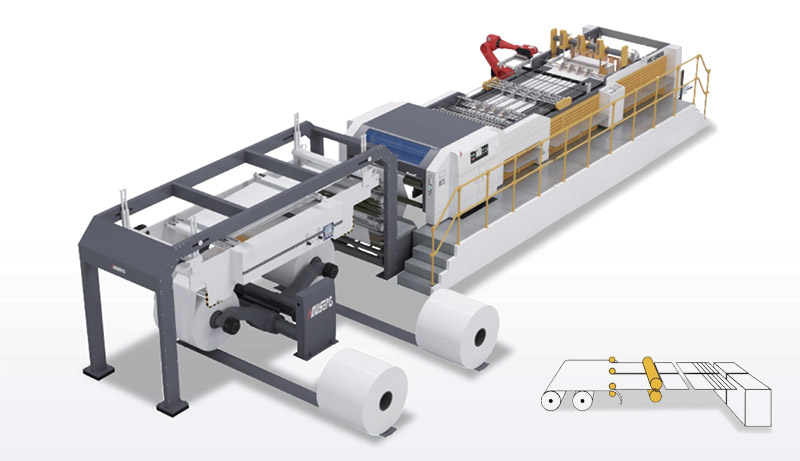

Zhejiang HaoSheng Intelligent Equipment Co., Ltd. : Double Rotary Sheet Cutting Machines

We released EXC Double Rotary Twin Knife Sheet Cutting Machine series in Nov. 2023.Combining with years of production experience, capturing customer needs, taking into account effciency and stability, EXC series perform superiorly in short length cutting, fully reflect HAOSHENG always dives to innovate.

This product adds the function of material weighing and paper stack height measurement, tacks on the workbench, pays attention to every small demand of customers, and improves the production experience. it performs particularly superior in the cutting length range length range of 400-65omm, with a maximum speed increase of73.8% compared to the standard.

Comparative Advantages

1. Material Weighing

Quickly access production data with material weight and stack height measurement for enhanced efficiency and accuracy.

2. High-Speed Cutting

Achieve up to 500 cuts per minute with cutting lengths from 400 to 650mm, ensuring fast and precise performance.

3. Full-Width Conveyor

Prevents paper edge impact and extends service life. The air suction system ensures stable and smooth transport.

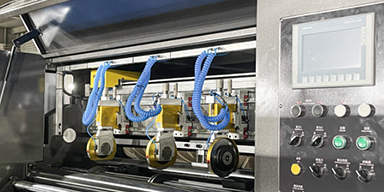

4. Static Control

Anti-static materials and static rollers work together to eliminate static and ensure smooth, high-speed operation.

Implementation Outlook

Market adoption of Double Rotary technology is projected to grow at 8.7% CAGR through 2030, particularly in:

- High-volume paper converting

- Technical textile processing

- Renewable material fabrication

- Next-generation packaging lines

Industry Impact Analysis

These cutting systems are revolutionizing manufacturing by:

✔️ Improving material utilization rates

✔️ Enabling thinner material processing

✔️ Reducing changeover times

✔️ Supporting sustainable production practices

2025/05/20

2025/05/20